Dronninglund Fjernvarme is a consumer-owned cooperative which supplies around 1,350 consumers with a 46 km DH network (2016). In 1989, Dronninglund Fjernvarme became the first Danish DH company to install natural gas-driven engines for CHP production. In 2005, the board and general assembly of Dronninglund Fjernvarme realized that they should replace natural gas with renewable energies. In 2007, Nordjyllands Vækstforum subsidized a pre-feasibility study, which showed that a large-scale solar thermal system with seasonal heat storage could cover up to 50% of the heat demand. Furthermore, the heat production price would not be increased for the consumers in case of a subsidized investment.

The project aimed to prove the feasibility of heat supply for DH networks with large-scale solar thermal plants and water pit heat storage (PTES). Furthermore, the utilization of PTES to store excess heat from waste incineration, industries and CHP production is analyzed. The plant started to operate in May 2014 (Check the figure below).

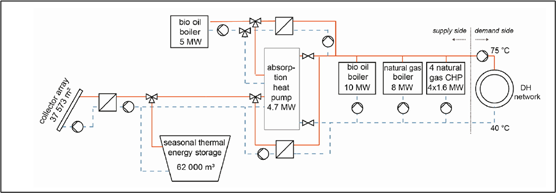

A simplified hydraulic scheme of the plant is shown in the figure below. The collector aperture area is 37,573 m2 (2,982 solar panels). The tilt of the solar collectors is 35° to maximize the annual solar yield. Each row of the collector array has up to 21 solar collectors connected in series. This is a typical number for collector arrays with harp-type collectors, as in Dronninglund, as the pressure drop becomes too high or the flow velocity becomes too small in the manifold pipes if more collectors are connected in series. Inlet temperatures of the collector array are around 40˚C in summer and can drop to around 15~20˚C in winter. Outlet temperatures reach 80~90˚C in summer and typically 30~40˚C in winter.

Hydraulic layout (simplified) of Dronninglund SDH. Pumps indicate flow direction in inlet/return pipes with lower temperatures (blue dashed lines) and outlet/supply pipes with higher temperatures (red solid lines) (source: Solites).

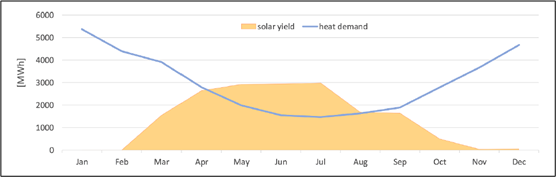

The seasonal pit thermal energy storage with a volume of 60,000 m3 was built in an abandoned gravel pit. The groundwater level is approximately 3 m below the bottom of the storage, and the soil consists of gravel and sand. The storage is insulated at the top with a floating cover. Insulation for the area which separates the water from the ground is economically not feasible. In summer (non-heating season), the solar thermal energy supply exceeds the heat demand of the connected consumers in Dronninglund (check the figure below). The surplus solar heat is used to heat up (charge) the PTES to a maximum temperature of 90 ˚C. The maximum temperature of the storage is determined by the liner material’s maximum tolerance temperature and lifetime. In autumn (heating season), hot water of the upper part of the storage is delivered to the DH network, while the cooler DH return flow enters the bottom part of the PTES with a temperature of around 40 ˚C (discharging). If the temperature in the upper part of the PTES is lower than the required DH supply temperature, the missing energy may be provided by the absorption heat pump with superheated hot water (160 ˚C), driven by the bio-oil boiler.

Monthly solar yield and heat demand of Dronninglund SDH (data: Solites)

The storage can be cooled down from 40 ˚C to 10 ˚C (about 30 K below the return temperature of the DH network) by using the storage as a heat source for the absorption heat pump. This has several positive effects on the system efficiency. First, the storage capacity is increased, i.e. with the same storage volume, more energy can be stored (higher temperature difference), and the storage can contain more heat in the next summer. Second, the average storage temperature is decreased, which reduces storage losses. Third, the efficiency of the solar thermal collectors is increased due to lower operating temperatures. In spring, autumn and winter, the bio-oil boilers and four gas engines cover the major part of the heat load, which is the conventional DH supply mode. In the measurement period, the solar fraction was 52%.

Dronninglund SDH was financed by an EUDP (Energy Technology Development and Demonstration Programme) project supported by the Danish Energy Agency. The subsidy was granted for detailed design and for investments in PTES, piping, heat exchangers and a control system to connect the production units. The subsidy of 21 million DKK (2.8 million EUR) amounts to around 20% of the total system cost. The specific costs were around 389 €/m2 collector aperture area. The heat price (before subsidies) is 50 €/MWh, which is slightly higher than typical SDH plants in Denmark due to the seasonal heat storage, high solar fraction and an advanced system concept with multiple heat supply sources.

Share this

Sector: District energy

Country / Region: Denmark

Tags: climate friendly government subsidies, energy efficiency, energy supply, engines for renewables, projects, soils, solar thermal, water resourcesIn 1 user collection: Sino-Danish Clean and Renewable Heating Cooperation Centre – Library

Knowledge Object: User generated Initiative

Publishing year: 2022